Architects, Engineers & Specifiers

Choose superior performance. Choose smart engineering. Choose unique design. Choose Trex®.

Contact Form

Why Architects & Specifiers Include Trex Fencing in Plans

When it comes to fencing for commercial and government applications, Trex® Fencing is the leading composite product. Trex is manufactured to meet the rigorous demands buyers rely on for perimeter fencing, trash enclosures, utility screens, and privacy barriers. Architects include Trex Fencing in plans for a variety of reasons: durable material, distinct appearance, flexibility in design, established brand, LEED point contribution, and more.

What is Trex?

Trex Fencing is a composite fence made from a proprietary blend of 95% recycled wood fiber and plastic. This unique product eliminates the negative attributes of a typical wood fence or vinyl fence while capitalizing on their virtues. Trex Fencing never needs painting or staining, won’t rot or decay, and will not become brittle or weak with age.

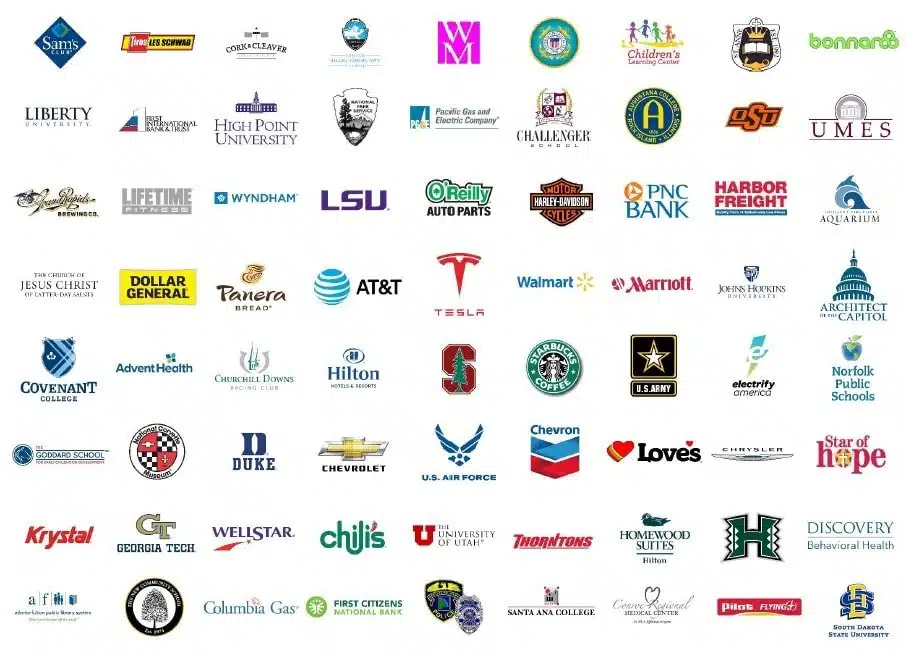

Who is Using Trex Fencing?

Trex Fencing is regularly being used as a product of choice for numerous municipalities, universities, retail locations, utility companies, and others in virtually any commercial market. Some of the well known buyers of Trex Fencing which have specified Trex Fencing as the material of choice include Electrify America, Love’s Travel Stops, Panera Bread, O’Reilly Auto Parts, Tesla, and Walmart. The architects for academic institutions, such as Louisiana State University, find Trex lends itself well to campus-wide plans to upgrade trash enclosures and perimeter fencing. Schools and hospitals often require tall utility equipment enclosures and Trex gives architects a value engineering option to propose that is much more affordable and easier to maintain than a masonry wall.

Architects Choose Trex for Height Adaptation

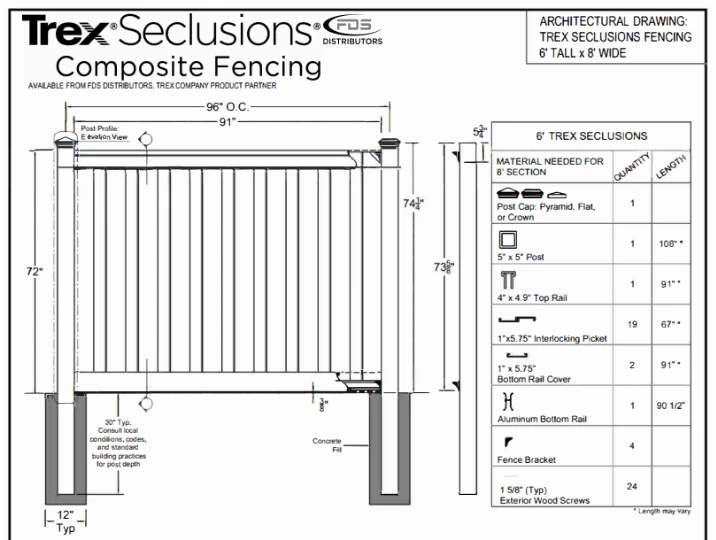

One of the best reasons architects include Trex Fencing in plans is its ability to adapt to various heights. From 2′ tall wall toppers to 12′ tall barriers, Trex Fencing is used in commercial applications to get the exact height needed. Trex fences are not made from pre-built panels, which provides a huge advantage when the fence has be adapted to fit a particular space, or needs to be shortened or heightened. While six ft. tall is the most common height for a fence, commercial projects often require eight ft. tall fences for perimeters or 10 ft. tall fence for HVAC equipment. Where necessary, steel post inserts and aluminum bottom rails give the Trex fence better rigidity and durability than other materials.

Fence Systems vs. General Design

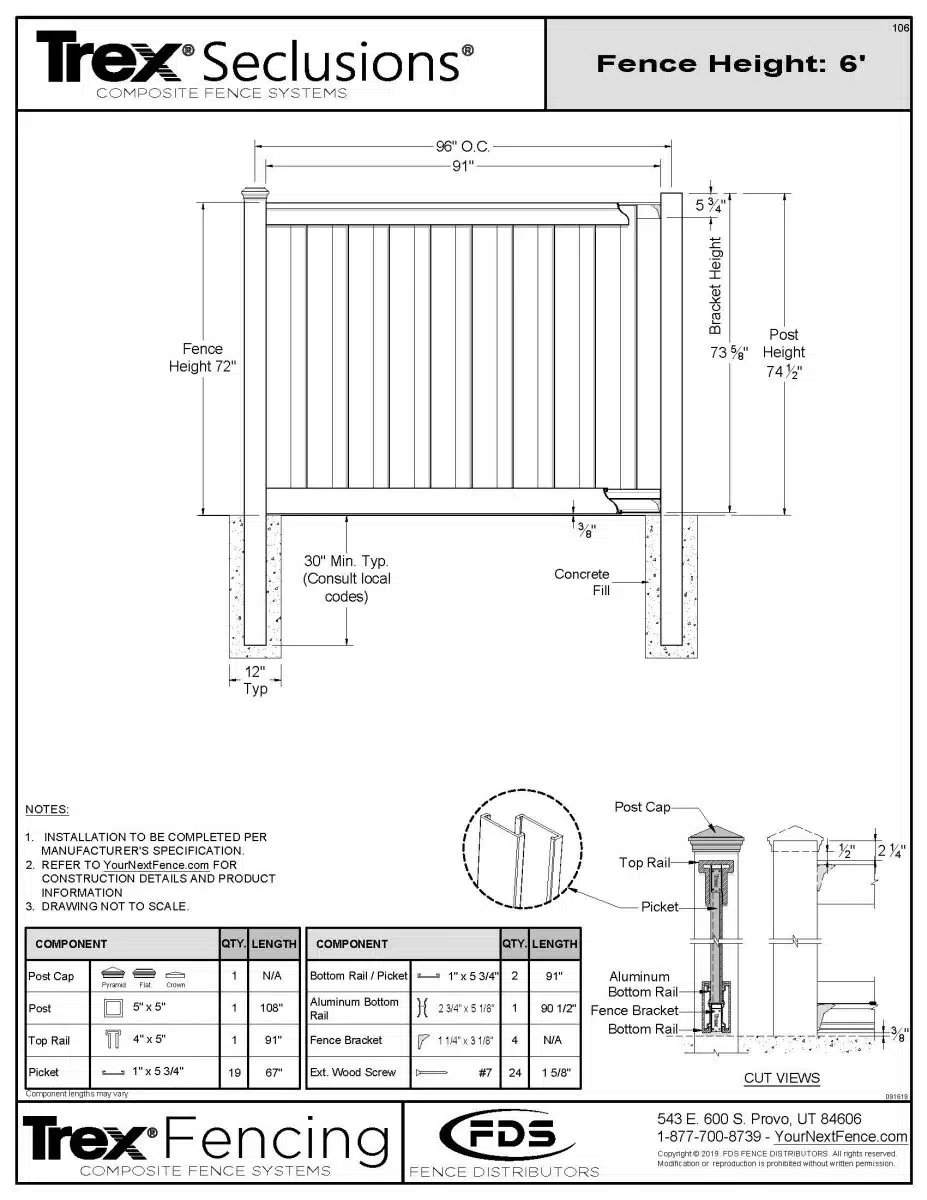

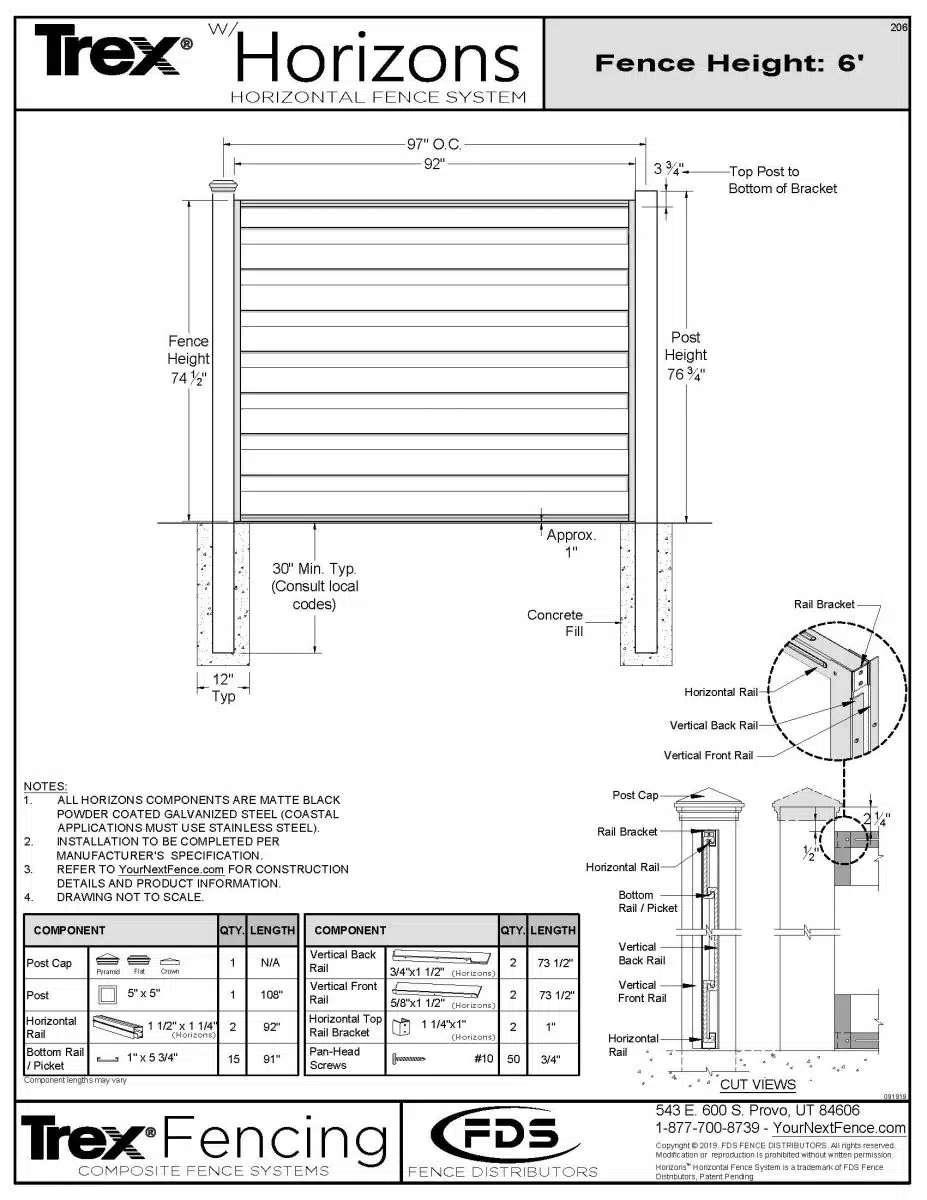

A significant advantage of the Trex Fencing systems (Seclusions for vertical picket orientation and Horizons for horizontal board orientation) is that they are fences with common configurations, standardized installation guides, and warranties. However, the distinct design of the fence systems give architects the ability to offer clients the appearance of an attractive customized fence without having to worry about misinterpretations of the specification.

Resources Available for Architects and Specifiers

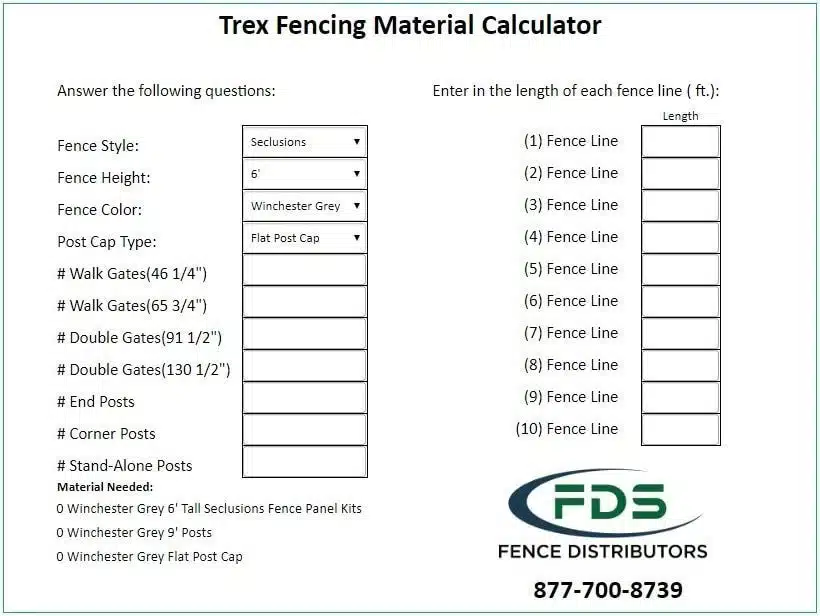

FDS Fence Distributors, the Trex fencing product partner, has created a large portfolio of drawings, technical data and other resources for architects and specifiers to help you include Trex fencing in your project.

Attributes of Trex Fencing

| Max Post Spacing | 8′ on center; can be cut down for shorter sections |

| Post Depth/Size | 30″ x 12″ typical (depends on soil conditions and fence height) |

| Fence Heights Available | Standard heights of 6′ and 8′, can be built from 2′ to 12′ |

| Stepping/Sloping |

The fence is made of individual components (not fixed panels) and bracketed so it can follow the grade or step; individual components can be replaced easily

|

| Low Maintenance | No painting or staining required; leading Wood/Plastic Composite |

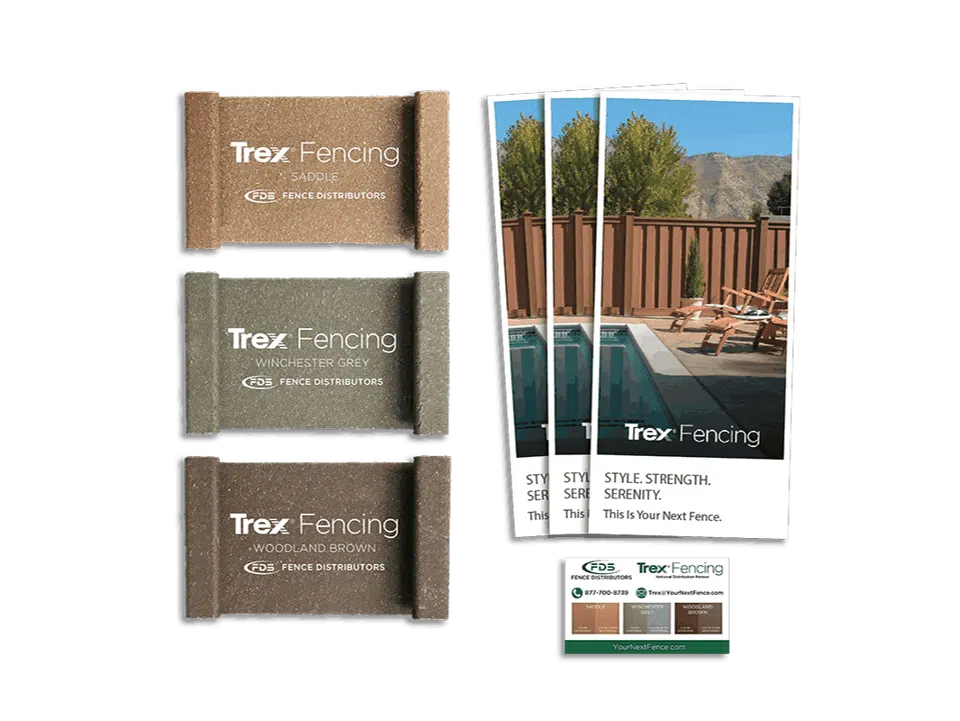

| Colors Available | Saddle (tan), Winchester Grey (light grey), Woodland Brown (dark brown) |

| Styles Available |

Seclusions (vertical board-on-board design), Horizons (horizontal board-on-board design)

|

| Green Materials |

95% recycled wood fibers and plastic (e.g., plastic bags); materials and manufacturing contribute LEED points

|

| Where is it Made | USA (specifically Fernley, Nevada) |

| Warranty | 25 year residential, 10 year commercial |

| Longevity of Company | Trex was founded in 1995 |

| Durability | Resistant to rot and decay; 130 mph sustained wind rating, 130 mph gusts (6′ tall); design resists warping |

LEED-Contributing Product

MATERIALS & RESOURCES

Credit 4.1 Recycled Content: 10% 1 point

Credit 4.2 Recycled Content: 20% 1 point

Note: Trex’s 95% recycled content far exceeds the minimum requirements set forth by the USGBC criteria.

Credit 5.1 Regional Materials: 10% 1 point

Credit 5.2 Regional Materials: 20% 1 point

INNOVATION IN DESIGN

Credit 1 LEED Innovation Credit 1 point