TECHNICAL DATA

Material Safety

(MSDS) contain information on the potential hazards (health, fire, reactivity, and environmental) in a given product. They also provide instructions on how to work safely with products that have hazardous chemicals. The data sheet available for Trex wood-polymer products designate it as stable with no significant physical/chemical or environmental hazards. As with any material, when working with Trex, take similar precautions as one would take when building with wood. Sawdust can be an irritant if inhaled or if exposed to eyes. Wear proper protection and use appropriate construction practices. Note: Trex Fencing has the same properties as the Trex Accents decking line that is denoted in the MSDS.

Acoustical Sound Rating

Acoustical Testing (External)

Trex Seclusions was submitted to a sound transmission loss test to evaluate acoustical properties. Intertek, the world’s largest testing agency, performed the evaluation. While a masonry wall is superior for this specific function, Trex Fencing is frequently used as a barrier because it provides a level of sound abatement needed for moderate reduction without the cost, construction limitations, and lack of appeal inherent in a concrete or block wall.

International Code Council

ICC-ES VAR Environmental Report (External)

The International Code Council (ICC) is a non-profit association responsible for the development of model codes and standards that are used for the construction process. The ICC’s International Building Code defines standards for designing, building, and compliance of structures for such elements as safety and sustainability. This report evaluates the content of Trex composites to provide information on the recycled content of the material. The report contains details on the eligibility of Trex recycled materials to the U.S. Green Building Council criteria for LEED point contribution. Learn more about Trex and LEED point contribution.

Made in U.S.A.

Made in the USA and Recycling Content Letter (External)

Trex Fencing materials are manufactured in the United States. Currently, all fencing is produced at Trex’s plant in Fernley, NV.

Fire Rating

Wind Load Testing

6ft High Wind Load Testing (External)

8ft High Wind Load Testing (External)

Creep Test

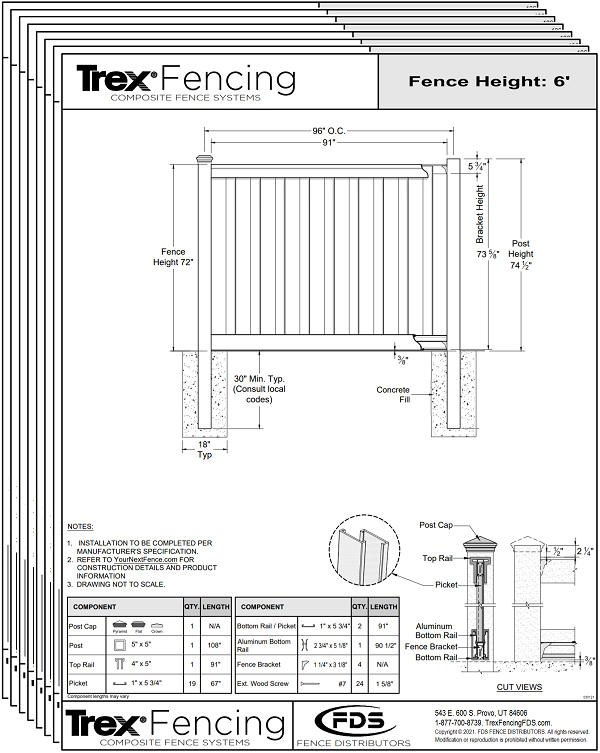

Component Weights and Pieces per Unit

Weights may vary due to density and nominal dimensions of the composite material

INDIVIDUAL COMPONENTS

| Nominal Piece Weight (lbs.) |

Product Description | Quantities in Full Units | Avg. Total Unit Weight (with pallet/box) |

| 37 | 5X5X8 TREX SECLUSIONS COMPOSITE POST | 36 | 1316 |

| 44 | 5X5X9 TREX SECLUSIONS COMPOSITE POST | 36 | 1630 |

| 57 | 5X5X12 TREX SECLUSIONS COMPOSITE POST | 27 | 1623 |

| 1 | 5X5 TREX SECLUSIONS POST CAP FLAT TOP | 12 | 12 |

| 1 | 5X5 TREX SECLUSIONS POST CAP PYRAMID | 12 | 12 |

| 28 | TREX SECLUSIONS TOP RAIL | 52 | 1450 |

| 10 | TREX SECLUSIONS ALUMINUM BOTTOM RAIL | 202 | 2066 |

| 8 | 91″ TREX SECLUSIONS BOTTOM RAIL COVER / PICKET | 154 | 1318 |

| 6 | 67″ TREX SECLUSIONS PICKET | 154 | 1185 |

| – | TREX SECLUSIONS FENCE BRACKET | 96 | 13 |

KITS AND SUPPLEMENTAL PRODUCTS

| Nominal Piece Weight (lbs.) |

Product Description | ||

| 149 | 6X8 TREX SECLUSIONS FENCE PANEL KIT | ||

| 199 | 8X8 TREX SECLUSIONS FENCE PANEL KIT | ||

| 92 | 4X6 TREX SECLUSIONS GATE PANEL | ||

| 115 | 5X6 TREX SECLUSIONS GATE PANEL | ||

| 26 | 6′ TALL HORIZONS FRAME KIT | ||

| 30 | 8′ TALL HORIZONS FRAME KIT | ||

| 36 | 9′ GATE POST STIFFENER (12 GA.) | ||

| 75 | 9′ GATE POST STIFFENER HEAVY DUTY (7 GA.) | ||

| 102 | 12′ GATE POST STIFFENER HEAVY DUTY (7 GA.) |